What you need to know about moisture in concrete

- Moisture in concrete matters.

- Moisture moves.

- Concrete does not like to rush, it should dry well..

- Concrete moisture must be measured.

- Checking the relative humidity: the presence of a tool for work.

- Excess moisture can be a problem.

In order to control the work and the budget, you need to know all aspects of the construction project. Nowhere is this more important than in the area of concrete moisture testing. Concrete is the foundation for key systems in most modern construction projects, so understanding the need for accurate moisture testing can be key to preventing problems in the future.

Moisture in concrete matters.

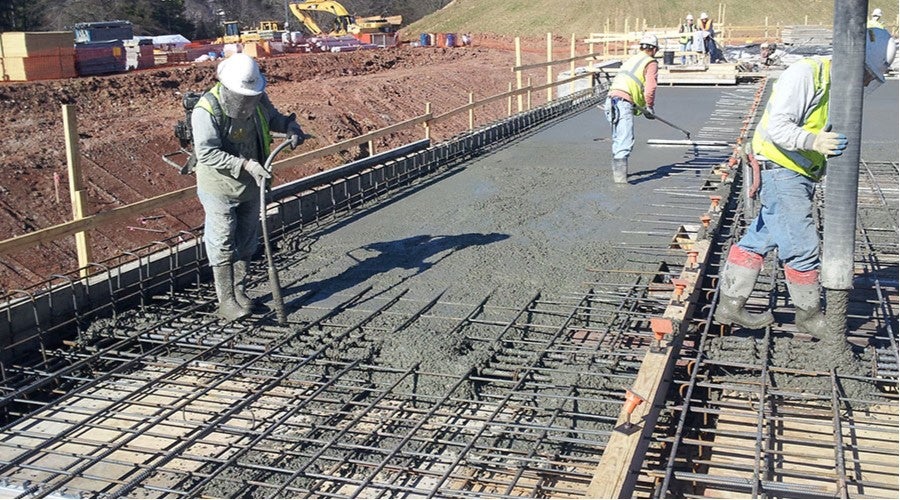

It may be obvious to say that moisture is a part of concrete, but given the damage that moisture intrusion or moisture-related problems do to the construction industry every year, it bears repeating: concrete has moisture.

For concrete, water is a key ingredient in the hydration process, which sets and hardens the cement portion of any concrete mix. Despite the rapidly changing innovations in admixtures and concrete, water is still part of every batch.

Why is this so important? Because if this primary water is not given time to leave the concrete slab, i.e. evaporate, it will cause damage, which in turn will damage the entire system and lead to health hazards due to the growth of mold and fungus. Moisture cannot be ignored in any construction project.

Movement of moisture in concrete.

From the initial mixture, the concrete is hydrated (or hardens), and then must release excess moisture during the drying process. During this process, a large percentage of the excess moisture in the slab must reach the surface and evaporate.

Moisture inside the concrete slab moves along paths that are formed as it combines with the original elements of the mixture – cement, aggregate and any other additives.

As it evaporates, more moisture moves up these paths in the cycle and creates a gradient effect within the slab. As long as the concrete is not sealed, this cycle usually means that the moisture level is higher in the depth of the slab. This is important to understand when choosing a concrete moisture test method.

It is also important to understand that this process can be reversed if the surrounding conditions around the stove have a higher humidity level than the stove itself. These pathways run in two directions, so unsealed concrete will also absorb moisture, either through contact with a direct water source (such as ground water or plumbing) or through ambient moisture.

Once the concrete is sealed, moisture continues to move inside the slab until it reaches equilibrium.

Do not accelerate the drying time of the concrete.

Applying a rule of thumb for concrete drying is all well and good (typically one month of drying time for every 2.5 cm of slab thickness), but the reality of concrete is that there are too many factors at play to predict when complete drying will occur.

There are a number of products or processes designed to speed up the drying time of concrete. Self-drying products in the starting mix, drying, changing environmental conditions, lower water content in the starting mix – all this is intended to accelerate the drying process by reducing the amount of moisture needed to obtain a strong and quick-drying concrete slab. However, if applied incorrectly, they can cause more problems than they fix. Mechanical processes can interfere with drying time. Hasty or ill-conceived grouting, surface curing, or any other process or material that minimizes the possibility of moisture escape. The time required for moisture to leave the stove will be significantly slowed down. Ambient conditions also greatly affect concrete drying time, so any change in relative humidity, air movement, temperature (relative to ambient relative humidity) will ultimately affect the final drying schedule.